Wonder Foam, a remarkable material, is revolutionizing industries with its exceptional properties and versatility. Its unique composition and characteristics set it apart from conventional foam materials, offering a myriad of advantages and applications.

From automotive engineering to healthcare, Wonder Foam is transforming product design and performance. Its lightweight, durability, and adaptability make it an ideal choice for various applications, leading to enhanced functionality and efficiency.

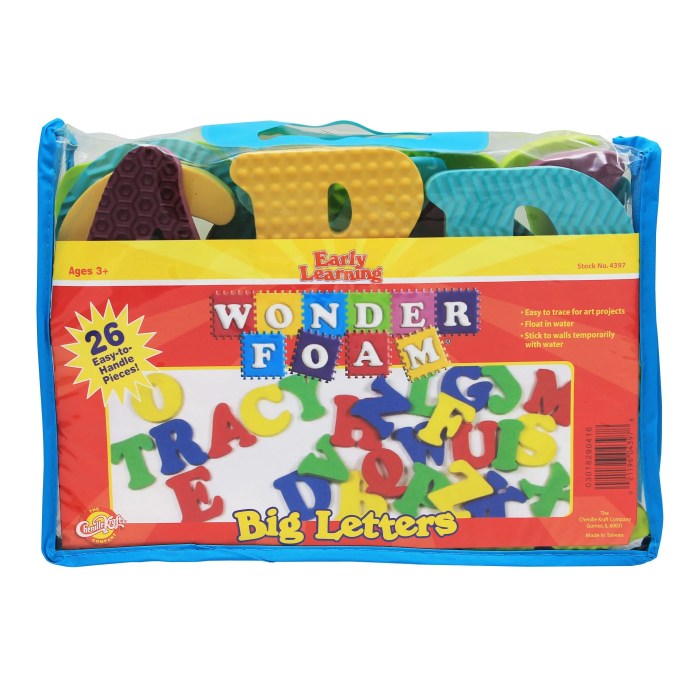

Product Overview

Wonder Foam is a revolutionary foam material composed of a unique blend of polymers and additives. Its composition grants it exceptional properties, including high elasticity, resilience, and durability. Unlike traditional foams, Wonder Foam exhibits superior resistance to compression, making it ideal for applications requiring sustained support and cushioning.

Wonder Foam’s versatility extends across various industries, including automotive, healthcare, and consumer goods. In the automotive sector, it is utilized for seat cushions and headrests, providing enhanced comfort and support during extended periods of driving. Within the healthcare industry, Wonder Foam is employed in medical mattresses and rehabilitation equipment, promoting pressure relief and improved patient outcomes.

Applications, Wonder foam

- Automotive: Seat cushions, headrests, interior padding

- Healthcare: Medical mattresses, rehabilitation equipment, prosthetic limbs

- Consumer goods: Sports equipment, toys, packaging materials

Manufacturing Process

Wonder Foam is manufactured through a meticulous process that combines innovative techniques with stringent quality control measures. The manufacturing journey begins with carefully selected raw materials, ensuring the foam’s exceptional properties and environmental sustainability.

Wonder foam is a lightweight and airy cleanser that gently removes impurities without stripping the skin of its natural oils. For those with acne-prone skin, the Cetaphil Acne Prone Foam Wash is an excellent choice. It contains salicylic acid, which helps to unclog pores and reduce inflammation.

Wonder foam is also a great option for those with sensitive skin, as it is fragrance-free and non-comedogenic.

Raw Materials

- Polyurethane:The primary component of Wonder Foam, polyurethane is a versatile polymer known for its durability, flexibility, and insulation properties.

- Isocyanates:These reactive chemicals are essential for creating the foam’s structure and density.

- Polyols:Polyols provide the foam with its flexibility and resilience, contributing to its comfort and longevity.

Production Methods

Wonder Foam is produced using a cutting-edge process that involves several key steps:

- Mixing:Raw materials are precisely blended to create a homogeneous mixture.

- Foaming:The mixture is then subjected to a foaming agent, causing it to expand and form the desired foam structure.

- Curing:The foam is allowed to cure, solidifying into its final shape and density.

- Cutting and Shaping:Cured foam is precisely cut and shaped to meet specific product requirements.

Quality Control

Ensuring the highest quality, Wonder Foam undergoes rigorous quality control checks throughout the manufacturing process. These measures include:

- Raw Material Inspection:Incoming raw materials are thoroughly inspected to meet stringent specifications.

- In-Process Testing:Foam samples are tested at various stages to monitor density, firmness, and other critical properties.

- Final Product Inspection:Completed products are inspected for dimensional accuracy, surface finish, and overall quality.

Environmental Impact and Sustainability

Wonder Foam is manufactured with a strong commitment to environmental sustainability. The production process employs energy-efficient technologies, and waste materials are minimized and recycled whenever possible. Additionally, Wonder Foam is certified by independent organizations to meet strict environmental standards.

Advancements and Innovations

The manufacturing process of Wonder Foam is continuously being refined through ongoing research and development. Innovations in raw materials, production techniques, and quality control methods are explored to enhance the foam’s performance, sustainability, and cost-effectiveness.

Applications and Use Cases

Wonder Foam finds versatile applications across diverse industries, offering unique advantages and performance benefits in each.

Automotive Industry

In the automotive sector, Wonder Foam serves as an exceptional soundproofing material. Its closed-cell structure effectively absorbs and dampens noise, creating a quieter and more comfortable cabin experience. Additionally, it is lightweight and durable, making it ideal for use in vehicle interiors, trunks, and engine compartments.

Construction Industry

Wonder Foam’s thermal insulation properties make it a valuable material in the construction industry. It provides excellent insulation against heat and cold, reducing energy consumption and enhancing building comfort. Its moisture resistance also prevents mold and mildew growth, contributing to a healthier indoor environment.

Packaging Industry

Wonder Foam excels as a protective packaging material due to its shock-absorbing properties. It safeguards delicate products during transportation, preventing damage and ensuring product integrity. Its flexibility allows it to conform to various product shapes, providing optimal protection.

Healthcare Industry

In the healthcare sector, Wonder Foam is used in medical devices and equipment. Its biocompatibility and hypoallergenic nature make it safe for use in close contact with the human body. It provides cushioning and support in orthopedic devices, such as prosthetics and braces, enhancing patient comfort and mobility.

Potential New Applications

Research and development efforts continue to explore new and innovative applications for Wonder Foam. Its unique properties hold promise in emerging fields, such as:

- Advanced filtration systems

- Biomedical engineering

- Sustainable packaging solutions

Properties and Performance: Wonder Foam

Wonder Foam exhibits exceptional physical and mechanical properties that contribute to its superior performance in various applications.

Its density ranges from 10 to 100 kg/m³, offering a balance between weight and strength. The foam’s elasticity allows it to recover its original shape after compression, ensuring durability and long-term performance.

Compression Strength

Wonder Foam’s compression strength surpasses that of traditional foams, withstanding high loads without permanent deformation. This makes it suitable for applications where shock absorption and load-bearing capabilities are crucial.

Thermal Insulation

The closed-cell structure of Wonder Foam provides excellent thermal insulation properties. It effectively reduces heat transfer, minimizing energy consumption and enhancing comfort in buildings and vehicles.

Comparison with Alternative Materials

Compared to polyurethane foam, Wonder Foam offers superior compression strength and thermal insulation. Its elasticity and durability make it a more reliable and long-lasting option.

In comparison to rubber, Wonder Foam is lighter and more flexible, making it ideal for applications requiring both cushioning and shock absorption.

Design and Engineering Considerations

When designing and engineering products using Wonder Foam, it is crucial to consider various factors that influence its performance and effectiveness. These factors include the shape, size, density, and load-bearing requirements of the product.

The shape of the product should be carefully considered to ensure optimal distribution of forces and minimize stress concentrations. The size of the product should be appropriate for the intended application, considering factors such as space constraints and weight.

Density and Load-Bearing Requirements

The density of Wonder Foam is a critical factor that determines its load-bearing capacity and stiffness. Higher density foams can withstand greater loads, while lower density foams provide better cushioning and impact absorption.

The load-bearing requirements of the product should be carefully assessed to determine the appropriate density of Wonder Foam. For applications involving heavy loads, higher density foams are recommended to ensure structural integrity and prevent deformation.

Examples of Successful Product Designs

Numerous successful product designs have utilized Wonder Foam’s unique properties. These include:

- Automotive interiors:Wonder Foam is used in seat cushions, headrests, and armrests to provide comfort and support.

- Medical devices:Wonder Foam is employed in prosthetics, orthotics, and cushioning for medical equipment.

- Packaging:Wonder Foam is used as protective packaging for fragile items, providing cushioning and shock absorption.

Last Word

Wonder Foam’s innovative nature and wide-ranging applications make it a material of the future. Its potential for advancements and sustainability initiatives further enhance its value. As industries continue to explore the possibilities of Wonder Foam, we can anticipate even more groundbreaking applications and transformative solutions.

FAQ Corner

What makes Wonder Foam unique?

Wonder Foam’s unique composition and structure give it exceptional properties, including high strength-to-weight ratio, flexibility, and thermal insulation.

In which industries is Wonder Foam commonly used?

Wonder Foam finds applications in diverse industries such as automotive, construction, packaging, and healthcare, due to its versatility and performance benefits.

How is Wonder Foam manufactured?

Wonder Foam is produced through a specialized manufacturing process involving advanced techniques and quality control measures, ensuring its consistent properties and performance.